Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

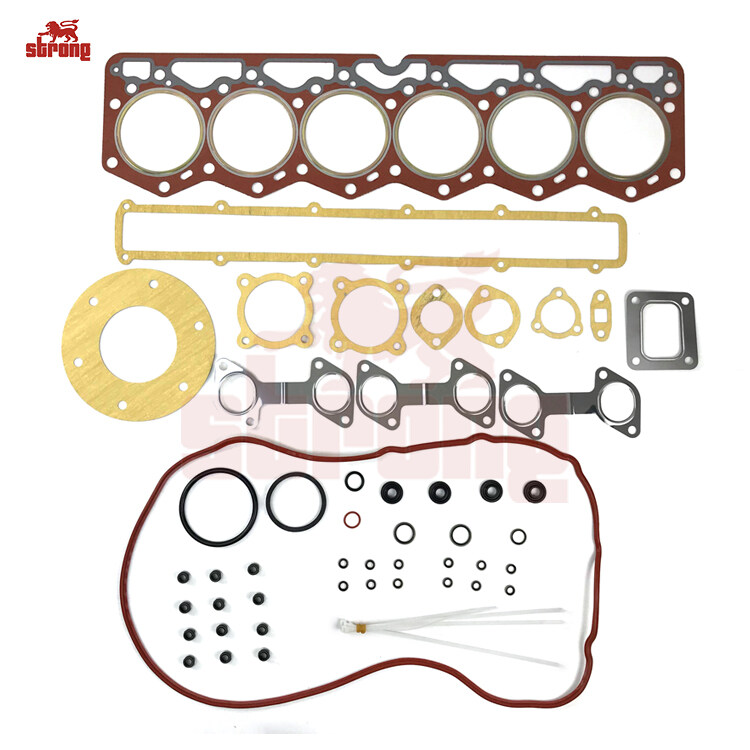

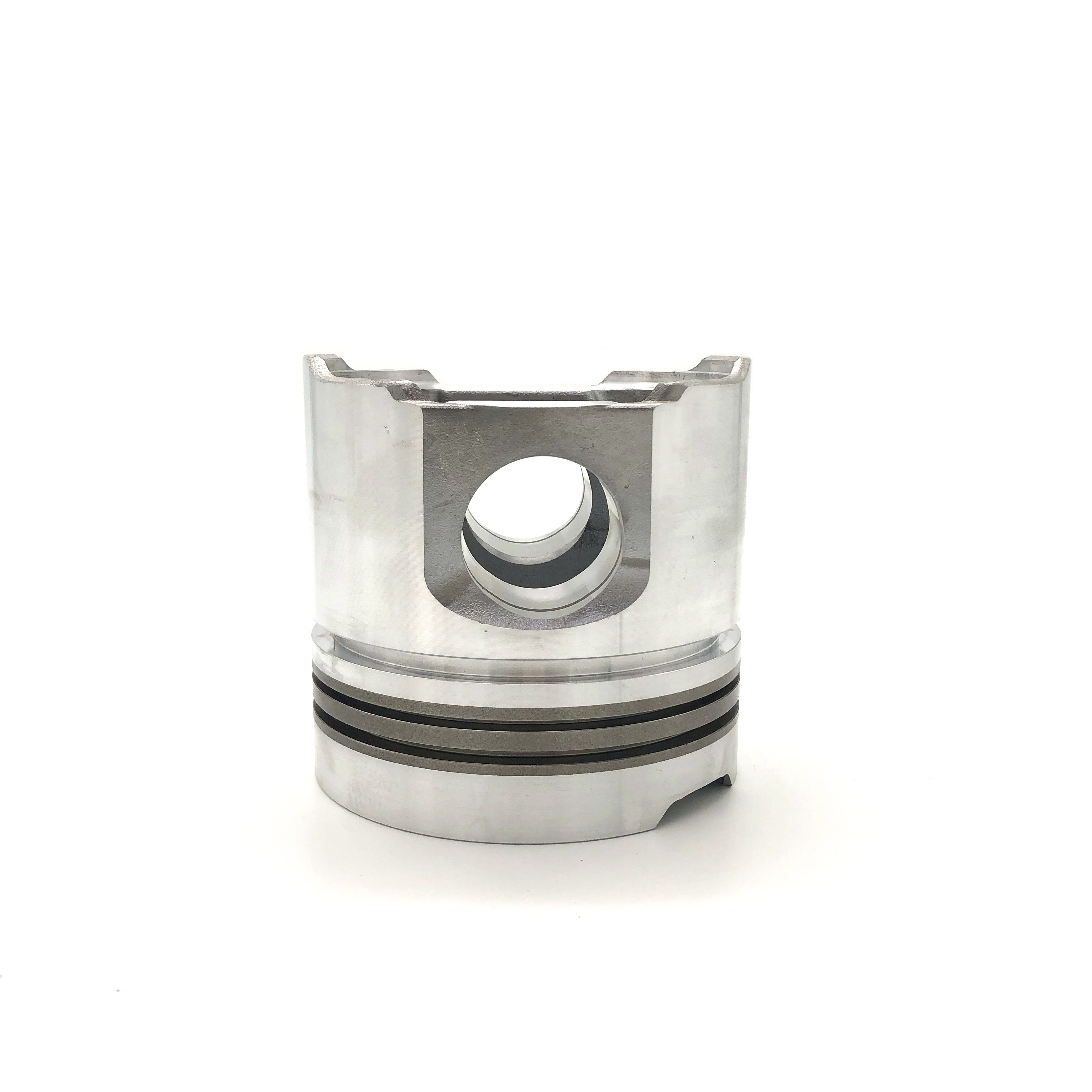

Caterpillar 3306 Diesel Engine Piston Set 8N3182

The 3306 Diesel Engine Piston Set is a critical component used in Caterpillar's 3306 engine, which is commonly found in various heavy equipment, industrial machinery, and construction vehicles

This piston set is designed to withstand the demands of heavy-duty diesel engine operation. Here's an overview of the key features and functions of the 3306 Diesel Engine Piston Set:

-

Materials and Construction: The piston set is typically manufactured using high-strength materials, such as aluminum alloy or steel, to endure the high temperatures and pressures generated during combustion. Pistons are often heat-treated for improved durability and wear resistance.

-

Ring Grooves: The piston set includes grooves for piston rings, which are responsible for creating a seal between the piston and the cylinder walls. Proper sealing prevents the escape of combustion gases and maintains compression.

-

Piston Crown: The piston crown, located at the top of the piston, is exposed to the high-temperature combustion process and must be heat-resistant and structurally robust.

-

Piston Skirt: The piston's skirt, the lower portion of the piston, helps guide the piston's movement within the cylinder and provides stability during the engine's operation.

-

Wrist Pin or Piston Pin: The wrist pin, also known as the piston pin, connects the piston to the connecting rod. It allows the piston to pivot and transfer the linear motion of the connecting rod into the rotary motion of the crankshaft.

-

Cooling Features: Some diesel engine pistons, particularly in high-performance engines, incorporate cooling features, such as oil jets or internal cooling channels, to manage the piston's temperature and prevent overheating.

-

Balanced Weight: Properly balanced piston design helps ensure that the reciprocating mass is evenly distributed, reducing vibrations and minimizing wear and tear on engine components.

Caterpillar 3306 Diesel Engine Piston Set Product Parameter:

|

Product Name |

Engine Piston Set |

|

Application |

Diesel Engine Parts |

|

Engine Number |

3306 |

|

Size |

STD |

|

OEM Number |

8N3182 |

|

Condition |

100% Brand-new |

|

Warranty |

6 Months |

|

Bore Diameter |

120.65mm |

|

Weight (kg) |

3 |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

Caterpillar |

|

Applicable Industries |

Machinery Repair Shops, Construction Works , Energy & Mining |

|

Packing |

Neutral Packing |

The engine piston set is designed with excellent pressure-resistant performance to withstand the high pressure generated during operation. Additionally, the lightweight design of the piston set reduces the engine’s inertia load and fuel consumption, thereby increasing its performance and efficiency. The piston set also features a high sealing capability, when combined with the piston ring, minimizing the risk of leakage.

Anti-corrosion:

The excellent corrosion resistance prevents damage caused by corrosion. The piston set is exposed to various fluids during the engine’s operation, including fuel, lubricating oil, and coolant, which can cause corrosion and damage to the piston set. Therefore, the material used for the piston set has excellent corrosion resistance to ensure that it can withstand prolonged exposure to these fluids without degrading or losing its performance. The piston set’s corrosion resistance is critical to prevent any damage caused by corrosion, which can lead to engine failure and reduced efficiency.

High Precision Machining:

The engine piston set goes through high-precision machining to ensure that the dimensions and surface quality of the piston set meet the required standards. High-precision machining is essential to ensure that the piston set fits precisely into the cylinder and operates smoothly. The piston set’s dimensions and surface quality directly affect the engine’s performance and efficiency. Therefore, the piston set is machined to high precision to ensure that it meets the required standards. High-precision machining can improve the piston set’s performance and efficiency by reducing friction and wear, improving sealing, and reducing vibration and noise. Additionally, high-precision machining can ensure that the piston set has a longer service life and can operate more reliably.

Fatigue Resistance:

It can well withstand prolonged high-frequency operation. The piston set is subjected to repeated stress cycles during engine operation, which can cause fatigue and eventually lead to failure. It can withstand prolonged high-frequency operation without degrading or losing its performance. The piston set’s fatigue resistance is critical to ensure that it can operate reliably and maintain its performance over a long period. Additionally, it can withstand the expected stress cycles during engine operation.

What are the types of pistons?

Because the internal combustion engine piston work in high temperature, high pressure, and high load conditions, the requirements of the piston are relatively high, so this article will mainly talk about the classification of the internal combustion engine piston.

1. According to the fuel used, can be divided into gasoline engine piston, diesel engine piston, and natural gas piston.

2. According to the material of the piston, it can be divided into cast iron piston, steel piston, aluminum alloy piston, and combination piston.

3. According to the manufacturing process of piston blank, it can be divided into gravity casting piston, extrusion casting piston, and forging piston.

4. According to the working condition of the piston, can be divided into two categories: non-pressurized piston and pressurized piston.

5. According to the use of the piston, can be divided into car piston, truck piston, motorcycle piston, marine piston, tank piston, tractor piston, lawn mower piston, etc.

The main role of the piston is to bear the combustion pressure in the cylinder and through the piston pin and connecting rod transfer this force to the crankshaft. In addition, the piston, cylinder head, and cylinder wall together form a combustion chamber.

The piston is a part of the combustion chamber, so it is often made of different shapes. Gasoline engine pistons are most often used flat top or concave top so that the combustion chamber structure is compact, small heat dissipation area, simple manufacturing process. Top pistons are often used in two-stroke gasoline engines. Diesel engine piston tops are often made into various concave pits.

The piston head is the part above the piston pin seat, and the piston ring is mounted on the piston head to prevent the high temperature and high-pressure gas from escaping into the crankcase and the oil from escaping into the combustion chamber. Most of the heat absorbed at the top of the piston is also transferred to the cylinder through the piston head and then transferred away through the cooling medium.

How to choose an engine piston?

When the cylinder wear exceeds the specified value and the piston is abnormally damaged, the cylinder must be repaired, and the piston should be selected according to the repaired cylinder size. The select piston should pay attention to the following points.

1. Select the piston with the same repair size and the same group size. The size of the piston skirt is the basis for a boring cylinder, that is, the cylinder repair size for which level, the piston repair size should also choose which level. Due to the grouping of pistons, after selecting the same grouping of pistons, only according to the size of the skirt of the selected pistons to bore and grind the cylinder.

2. The same engine must use the same brand of pistons. Pistons should be matched as a set to ensure the consistency of their materials and performance.

3. Supporting sets of pistons, size difference, and quality difference should be in line with the requirements. For the whole set of pistons, the size difference is generally 0.02 ~ 0.025mm, the quality difference is generally 4 ~ 8g, and the color code of the pin seat hole should be the same. The piston and cylinder of the new car use the matching method. In the premise of determining the technical requirements of the cylinder, the key is to match the corresponding piston. Piston repair size is generally divided into +0.25mm, +0.50mm, +0.75mm, and +1.00mm four levels, some only one or two levels. Each restoration size level is divided into several groups, usually into 3~6 groups, and the diameter difference between two adjacent groups is 0.010~0.015mm.

For selection and matching, pay attention to the piston grouping mark and coloring mark. For some engines for thin cylinder liners, the piston does not set the repair size, only distinguish the standard series piston and repair series piston, each series piston also has several groups for optional.